Why 3D Prints?

Something I seem to hear fairly often is "Why don't you just make everything from fibreglass?". To that I have to say, "Have you ever actually dealt with fibreglass?!".

Now let me explain, fibreglass, when worked with properly, can be amazing. It has brought the elusive world of custom car building to the mainstream, and it is no doubt here to stay.

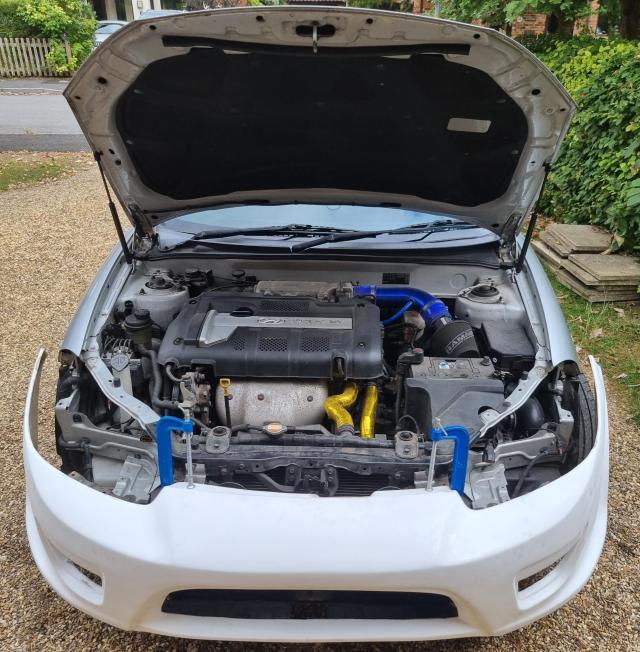

However, there's a reason those high end kits cost so damn much. It's because it takes a serious skill in order to do what they do, and deliver a consistent, high quality, usable fibreglass component, everytime. Having been on the receiving end of a cheaper one, I can safely say that you most definitely get what you pay for. See the image above of my Hana bumper for my 2007 SIII, that I paid a decent chunk of change for, happily sitting a foot wide on each side...

So, when it came to making my own parts, I set myself three non-negotiables:

1. Make it fit well.

2. Make it easy to process.

3. Make it affordable.

This immediately ruled out fibreglass. Despite its benefits, it simply has too many cons to make small production parts affordable. 3D printing on the other hand, that was very much affordable by comparisson, and very, very consistent.

3D printing can get a bad wrap, probably due to it being fairly new and not well understood; but year after year it continues to improve, with new materials allowing for specialist components to survive in brutal conditions, new capabilities in printing, allowing for more and more complicated components, and new speeds. Good lord the speed of 3D printing...

So that is why here at Black Stag, we are focusing so heavily on FDM 3D printing techniques, since they are what allow us to bring these components to life, on a budget, and make them accessible for everyone else.

Make sure to check out our range of products and give the "Our History" page a read if you're interested in the backstory behind Black Stag.